Respiratory protection in the workplace can often be overlooked because the effects don’t immediately indicate defective occupational safety like other forms of physical trauma. But, respiratory problems can exhibit severe long-term health defects.

Employees required to work in hazardous environments containing harmful dust, fogs, fumes, mists and other dangerous gases and vapors can ingest these exceptionally quickly and easily without adequate respiratory protection and other personal protective equipment (PPE).

For this reason, OSHA has established a respiratory protection standard for employers and workers alike to ensure adequate air quality and that respiratory hazards in the workplace are addressed.

Here’s everything you need to know about the OSHA respiratory protection requirements to ensure compliance.

How to Detail a Compliant Respiratory Protection Program

If workers are at risk of inhaling hazardous materials such as fogs, fumes, mists, gases and dust that can’t be contained by engineering or administrative control, OSHA standards call for a written respiratory protection program to ensure occupational safety.

Engineering controls could include:

- substituting substances with non-hazardous ones where applicable, or

- using ventilators.

Administrative controls could be:

- enforcing worker rotation, or

- regular breaks.

If respiratory protection is required, the respiratory protection program must detail:

- how the respiratory protection program will be administered, and

- how the respiratory protection program will be enforced.

This written program must include the following:

- Respirator selection

- Proof of medical evaluation

- Employee training

1.) Respirator Selection

As the employer, you must facilitate an exposure assessment and a hazard control evaluation to establish which air-purifying respirator is appropriate for your workers’ occupational safety and health that meets the OSHA respiratory protection standard.

A qualified health and safety professional must evaluate the workplace to determine:

- the respiratory hazards present, and

- the exposure levels.

They should then provide the exposure limit and indicate whether the exposure levels produced at your workplace require workers to use respiratory protection.

If it’s found that respiratory protection is required, it must be approved by the National Institute for Occupational Safety and Health (NIOSH) and then recorded in the respiratory protection program.

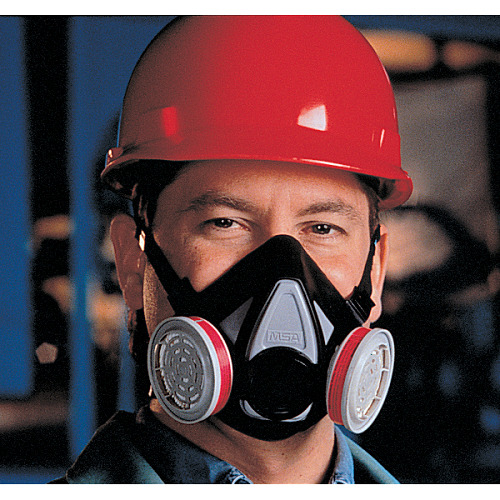

Respirators can include self-contained breathing apparatus (SCBA), which are atmosphere-supplying respirators where the breathing air source is designed so the user can carry it.

Other types of respirators that meet the OSHA respiratory protection standard include:

- air-purifying respirator,

- atmosphere-supplying respirator

- demand respirator,

- escape respirators,

- negative pressure respirator (tight fitting),

- positive pressure respirator,

- powered air-purifying respirator (PAPR), and

- pressure-demand respirator.

Note that respiratory protection isn’t the only option. Employers must perform a hazard control evaluation to establish whether engineering or administrative controls are a viable solution without needing personal protective equipment.

2.) Proof of Medical Evaluation

Medical evaluations are required to confirm workers fit to wear respirators and use the appointed respiratory protection.

As part of the medical evaluation, OSHA standards require workers to fill out a questionnaire about:

- medical conditions that could hinder their ability to wear respiratory protection, and

- conditions and hazards they face that hinder occupational safety and health.

Then, a physician or other licensed healthcare professional must perform a medical evaluation to determine any unforeseen reasons why a worker may not be able to use the appropriate respiratory protection safely.

The healthcare professional must provide a medical evaluation note for each worker. Records of medical evaluations must be stored in the respiratory protection program.

Once the medical evaluation assesses that a worker is safe to use the respiratory protection, they must go for fit testing. Fit testing procedures are performed to determine the quantitative fit of the respiratory protection equipment. It must be tight-fitting and pass the fit test.

3.) Employee Training

Because toxic fumes can be immediately dangerous to life and result in emergency situations, employers must ensure adequate respiratory protection training.

The respiratory protection program must outline the training program, and an up-to-date record must be kept of when the training was performed and who received it. Absent workers must receive training as soon as possible, and refresher training must take place annually. This must include any new equipment, machinery, or anything else affecting the use of respiratory protection.

As per OSHA standards, respiratory protection training must include:

- what the respiratory protection does,

- how the respirator provides protection,

- how to inspect the respiratory protection equipment for defects,

- how to ensure the proper respirator fit,

- how to put on and take off the respiratory protection,

- how to clean and disinfect respiratory protection equipment,

- how to identify medical signs and symptoms suggesting the use of respiratory protection may be unsafe,

- maintenance procedures of respiratory protection equipment, and

- storage procedures of respiratory protection equipment.

Respiratory Protection Program Evaluation

The employer must appoint a respiratory protection program administrator to facilitate the program according to OSHA standards.

The administrator’s responsibility is to ensure the written program and all relevant records are up to date. They should also regularly review and update training requirements, including the annual refresher and training of new staff members.

Administrators are responsible for observing and talking to workers required to wear respiratory protection. They should continually evaluate that the respiratory protection meets employee needs and is correctly and adequately understood. In addition, administrators must conclude whether the training was sufficient according to use, fit, maintenance and cleaning.

The program administrator should record all findings in the respiratory protection program. Corrective measures should be implemented and recorded.

How Insure Compliance Can Help Employers Reach the OSHA Respiratory Protection Standard For Occupational Safety

At Insure Compliance, we perform a gap analysis using our Safety Gap Model to find areas of your company safety program that need to be addressed. Weak links can result in poor safety culture. This can compromise occupational safety and health and lead to OSHA violations.

Here are the safety gaps that could be present in your company:

- Awareness gap: knowing the correct respiratory protection appropriate for your employees.

- Process gap: detailing workplace policies in a respiratory protection program.

- Knowledge gap: enforcing the respiratory protection program.

- Verification gap: evaluate the respiratory protection program’s effectiveness by engaging with employees and inspecting behavior.

- Accountability gap: keep employees accountable for respiratory protection program violations.

We can assist with establishing properly implemented safety policies detailed in the written respiratory protection program according to OSHA respiratory protection standards and appropriate safety training.

Key Takeaways

Employers needing to meet the OSHA respirator requirements and uphold occupational safety and health must compile a written respiratory protection program.

This program will help allow employers to:

- select the appropriate respiratory protection,

- ensure workers may use respiratory protection without compromising their health, and

- establish appropriate respiratory protection policies and training.

The respiratory protection program should be evaluated and updated regularly to meet the OSHA respiratory protection standard and maintain occupational safety and health.

If you want to address your company respiratory protection requirements safety gaps, contact us today to help you establish and implement a respiratory protection program.

Disclaimer:

Please note that every effort has been made to ensure that the information provided in this guide is accurate. You should note, however, that the information is intended as a guide only, providing an overview of general information available to businesses. This guide is not intended to be an exhaustive source of information and should not be seen to constitute legal, safety or business advice. You should, where necessary, seek your own advice for any issues raised in your affairs.

One Response